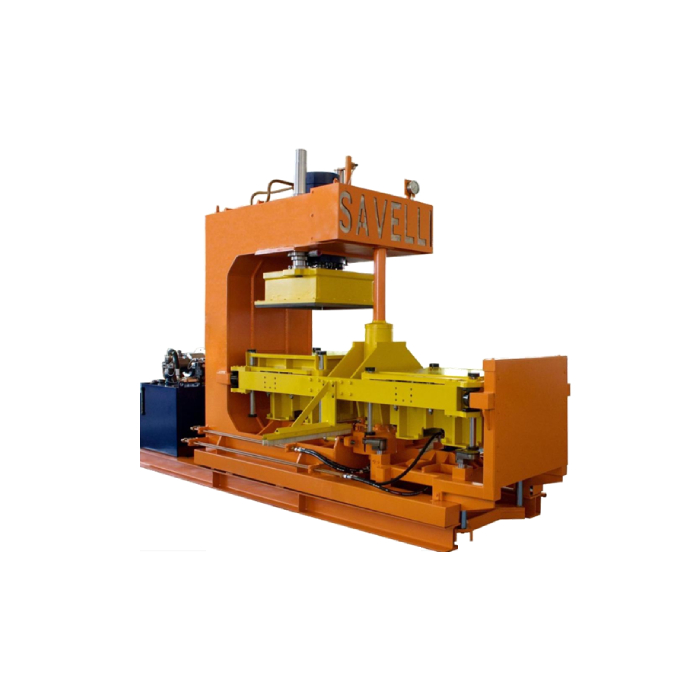

SAVELLI, leader in the production and installation of high-tech moulding lines and sa

nd plants for Green Sand Foundries, has developed new machines for foundries that would like to step into High Pressure Moulding Technology.

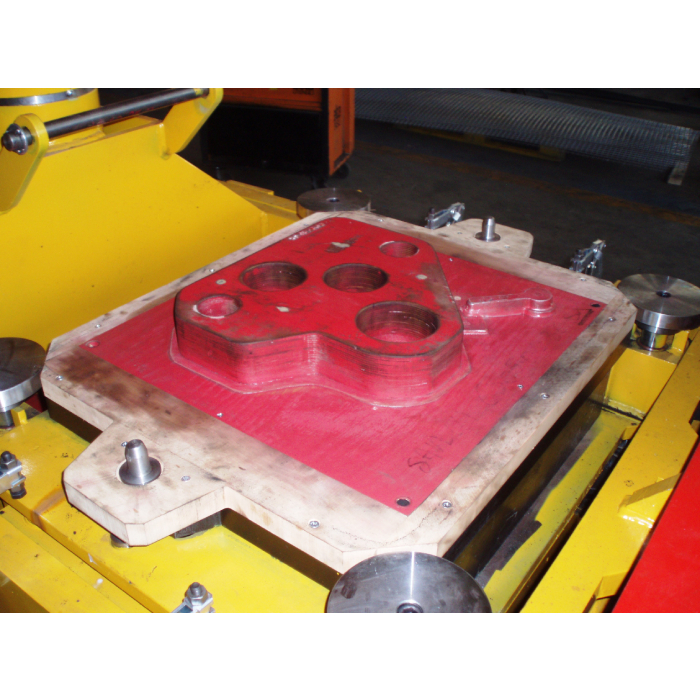

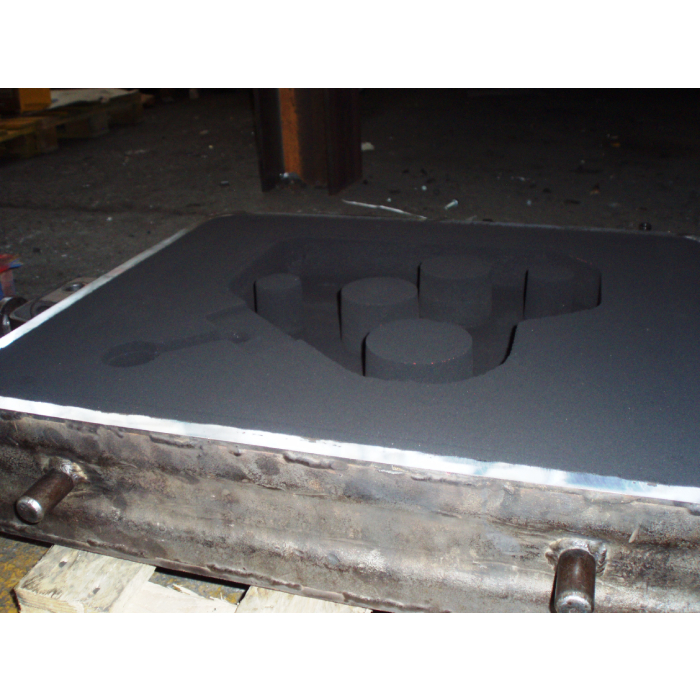

Existing Jolt Squeeze Patterns can be used.

Jolt Squeeze Flask can be used with minor modification.

High dimensional moulding accuracy.

Options with Squeeze plate and Multipiston systems.

Mould pre compaction by Gravity, turning potential energy in Kinetic.

Moulding pressure adjustable from 2-12 Kg/cm2.

Sand Feeding system options :

- With existing sand hopper and Fish mouth gate system.- Batch hopper with / without weighing system.

Sand distribution - Manual

Turn table design – Rotary pattern transfer

Control panel with PLC. Friendly Touch panel HMI

Built in Modem in Control panel for On line support

Noise level < 80dB